Moore Jig Grinder Remanufacturing

Before

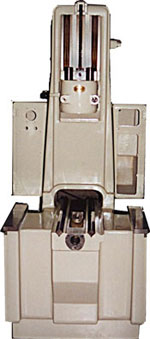

In-Process

After Completion

NASA Machine Tools has the ability to remanufacture your existing Moore jig grinder, or to supply a completely remanufactured machine, including the Moore jig grinder frame. After completion, NASA guarantees that each machine will achieve the original factory specifications. The following features and specifications are included:

STANDARD SPECIFICATIONS: (No.3 or G-18 Size Machine)

- Table Size 11” x 24”

- Table Travel X Axis 18”

- Table Travel Y Axis 11”

- Spindle Housing Vertical Travel 12 5/8”

- Spindle Vertical Travel (Quill) 3 5/8”

- Table Top to Wheel Collet 2” to 18”

- Spindle Column to Ways 10”

- Spindle Column Below Ways 13 ½

- Angular Adjustment of Spindle up 1 ½ degrees

REBUILD FEATURES:

- X & Y Axis digital readout system with .000010” resolution

- New main spindle bearings and outfeed bearings

- New Ross valves

- New u-cups, packing, seals and o-rings

- New bib and apron

- New link and link pins

- New hoses and head thermometer

- Rebuilt by-pass valve assembly

- Remanufactured vertical slide assembly to include grinding of the keyway, and new “FIT” of the slide and sleeve

- New micro switches for chop and head

- Rework of the lead screws

- Oil bath for lead screws

- Precision hand scraping of the table, saddle and column for geometry correction (corrects flatness, parallelism, squareness and perpendicularity)

- Spotting of the table surface

- Two (2) coats of high gloss epoxy paint

- One (1) year warranty/guarantee

- Positioning accuracy .000090”

NASA’s goal is to provide the most cost-effective, high-quality jig grinders and related products and services to our customers, with the best customer service in the field. It is much cheaper to remanufacture than to replace a used jig grinder, and the original accuracy can be maintained. So contact NASA today and let our experienced technicians help you determine the most economical and efficient products and services to meet your business needs.