Moore Jig Grinder Rebuild and CNC Integration

NASA Machine Tools has been rebuilding and converting Moore jig grinders into CNC, continuous path machines since 1985.

NASA Machine Tools has been rebuilding and converting Moore jig grinders into CNC, continuous path machines since 1985.

To date, we have converted hundreds of machines and have installations in some of largest jig grinding companies in the world.

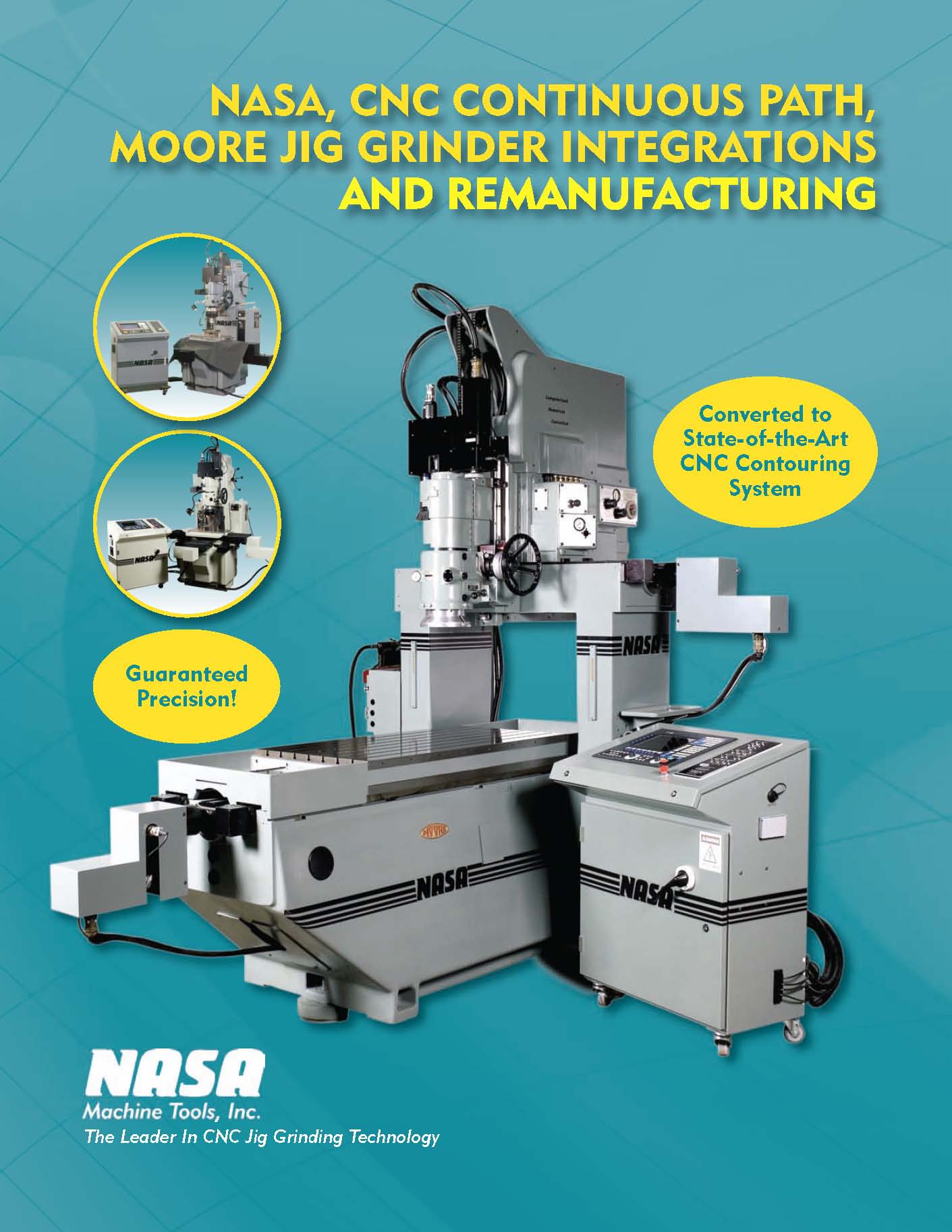

Utilizing existing Moore jig grinders, including No.3’s, G-18’s, G-32’s, G-48’s, series 1000’s, and existing Moore CNC’s , NASA completely remanufactures, and converts your existing machine, into a state-of-the-art, CNC continuous path system.

With the successful integration of specialized components, part tolerances and finishes in contouring, and point-to-point jig grinding of holes are achieved well within the standard tolerances for CNC jig grinders.

Each machine that is remanufactured in our Lincoln Park, NJ facility, is guaranteed to be as accurate as any new machine offered, and carries the original equipment manufacturer’s specifications.

Our remanufacturing and CNC integration includes the following:

- FAGOR 8055, or FANUC 21I, CNC control system with LCD color display and graphics capability

- 10.5 “ CNC cross travel (Y axis)

- 17.5” CNC longitudinal travel (X axis)

360 degrees CNC rotation of C axis (Automatic C axis normalcy)

360 degrees CNC rotation of C axis (Automatic C axis normalcy)

- Rapid traverse rate 60 IPM

- Contouring rate 15 IPM

- Ultra precision ball screws on the X & Y axes, w/5000 line encoders mounted directly on the ball screws for high accuracy

- Precision roller bearing way system with accordion way covers

- Oil bath for ball screws

- Closed loop servo drive motors and servo drive system

- Automatic lubrication system with low oil sensors

- PROGRAMMABLE main spindle speeds 0-300 RPM (PLANETARY)

- PROGRAMMABLE chop grind ON/OFF with head up micro switch

- PROGRAMMABLE air grinding spindle ON/OFF

- PROGRAMMABLE 110V outlets ON/OFF

- Absolute programmable U axis outfeed (OPTIONAL)

- Manual pulse generator (hand wheel)

- X, Y & C home switches and indicator lights

- X & Y limit switches and indicator lights

- Minimum programmable resolution

- Stand-alone control cabinet with electronics

Three (3) coats of high gloss epoxy paint

Three (3) coats of high gloss epoxy paint

- Complete mechanical rebuild including:

- New main spindle bearings

- New outfeed bearings

- New U-cups, packing, seals and o-rings

- New link and link pins

- New micro switches

- New chop valves (2-way and 4-way)

- Re-grind quill keyway, and “FIT” slide and sleeve

- Hand scraping of the column, table, and saddle for geometry correction

- Spotting of the table surface

- Lapping of the table and saddle for proper roller bearing contact

- New main spindle bearings

- One (1) year warranty/guarantee on entire system

- Positioning accuracy .000080”

- Contouring accuracy .000200”

OPTIONAL FEATURES:

- Absolute programmable U axis outfeed

- Programmable 5th axis rotary table

High speed reciprocation package

High speed reciprocation package

- Portable manual pulse generator (hand wheel)

Rebuilding and converting your existing Moore jig grinder is more cost-effective than replacing it with a new machine. Our many years of experience in rebuilding and converting them to CNC, continuous path machines together with our goal of providing the most economical pricing in the field make us the first choice for all of your Moore jig grinder needs. We offer quality, reliability, accuracy and unsurpassed service and support, at a price you can afford, so contact NASA today.